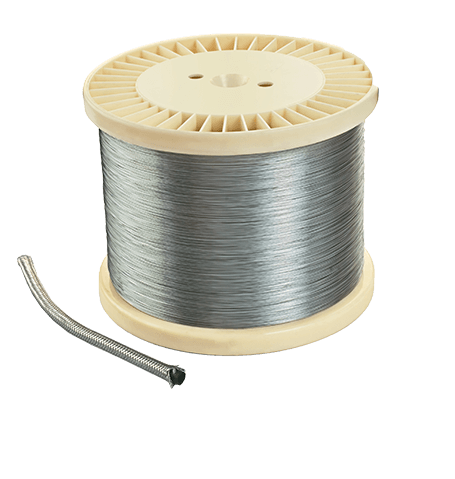

Spring Wires

KEl’s Stainless Steel Wire for Springs are manufactured having excellent mechanical properties (surface, cast & helix) manufactured under strict guidance of technical people, diameter from 0.19 mm to 1.20 mm in bright finish and 0.50 mm to 6.0 mm in matte finish (coated) in grade of AISI 302, 304 & 316, 321, Standard ASTM A313 and others.

Rope Wires

KEl’s Stainless Steel Wire for wire rope are manufactured having excellent mechanical properties, under strict guidance of technical people, diameter from 0.19 mm to 1.20 mm in bright finish and 0.50 mm to 6.00 mm in matte finish (decoated) in grade of AIS1304, 316,321 rope specs.

Stainless Steel Wire for springs has following Characteristics

- Excellent surface finish

- High corrosion resistance

- Superior coiling efficiency

- High Fatigue strength

Stainless Steel wire for spring is made from the selected steel. In particular to provide optimum spring efficiency, this type of wire is painstakingly finished to eliminate flaws.

Ovality of the wire

The arithmetic difference between the two measurements of the diameter shall be not more than half the tolerance specified in table 1.

| Table 1 – Tolerances On Diameter | |

|---|---|

| Nominal Dia of wire d | Tolerance on diameter |

| 0.2+/-0.01 | |

| 0.4 < d < 0.6 | +/-0.015 |

| 0.8 < d < 1 | +/-0.02 |

| 1 < d < .6 | +/-0.02 |

| 1.6 < d < 2.4 | +/-0.03 |

| 2.4 < d < 3.7 | +/-0.03 |

| 3.7 < d < 5.2 | +/-0.04 |

| 5.2 < d < 6 | +/-0.05 |

| values in millimetres | |

Tensile Grades

The tensile grades of wires are

- 1570 N/mm2 for wires of all qualities

- 1770 N/mm2 for bright wires quality B

- 1960 N/mm2 for bright wires quality B

These nominal values are the lower limits of strength. The upper limits are equal to the lower limits in addition to the tolerance specified in table 2.

| Table 2 – Tolerances On Tensile Grade | |

|---|---|

| Nominal dia of wire d | Tolerance on tensile grade |

| Nominal dia of wire d | Tolerance on tensile grade |

| mm | N/mm2 |

| 0.2 < d < 0.5 | 390 |

| 0.5 < d < 1 | 350 |

| 1 < d < 1.5 | 320 |

| 1.5 < d < 2 | 290 |

| 2 | 260 |

Note : Other tensile grades may be used on agreement between the manufacturer and the supplier.

Reverse Bend Strength

This test applies only to wire of nominal diameter between 0.5 mm inclusive ad 3.7 mm inclusive. For wires of nominal diameter less than 0.5 mm.

The wire shall withstand without breaking the minimum number of reverse bends specified in table 3 for the appropriate diameter, tensile grade and finish. The radius of curvature of the supports for the various wire diameters is also given.

| Nominal Dia of wire d mm | Radius of curvature of supports mm | Minimum number of reverse bends | |||

|---|---|---|---|---|---|

| Quality B | Quality A | ||||

| Tensile grade N/mm | |||||

| 1570 | 1770 | 1960 | 1570 | ||

| 0.5 < d < 0.55 | 1.75 | 15 | 14 | 13 | |

| 0.55 < d < 0.6 | 14 | 13 | 12 | ||

| 0.6 < d < 0.65 | 12 | 11 | 10 | ||

| 0.65 < d < 0.7 | 11 | 10 | 9 | ||

| 0.7 < d < 0.75 | 2.5 | 15 | 14 | 13 | 12 |

| 0.75 < d < 0.8 | 14 | 13 | 12 | 11 | |

| 0.8 < d < 0.85 | 13 | 12 | 11 | 10 | |

| 0.85 < d < 0.9 | 11 | 10 | 9 | 8 | |

| 0.9 < d < 0.95 | 10 | 9 | 8 | 7 | |

| 0.95 < d < 1 | 10 | 9 | 8 | 7 | |

| 1 < d < 1.1 | 3.75 | 15 | 14 | 13 | 12 |

| 1.1 < d < 1.2 | 13 | 12 | 11 | 10 | |

| 1.2 < d < 1.3 | 12 | 11 | 10 | 9 | |

| 1.3 < d < 1.4 | 10 | 9 | 8 | 7 | |

| 1.4 < d < 1.5 | 9 | 8 | 7 | 6 | |

| 1.5 < d < 1.6 | 5 | 12 | 11 | 10 | 9 |

| 1.6 < d < 1.7 | 11 | 10 | 9 | 8 | |

| 1.7 < d < 1.8 | 10 | 9 | 8 | 7 | |

| 1.8 < d < 1.9 | 9 | 8 | 7 | 6 | |

| 1.9 < d < 2 | 8 | 7 | 6 | 5 | |

| 2 < d < 2.1 | 7.5 | 13 | 12 | 11 | 10 |

| 2.1 < d < 2.2 | 12 | 11 | 10 | 9 | |

| 2.2 < d < 2.4 | 11 | 10 | 9 | 8 | |

| 2.4 < d < 2.5 | 10 | 9 | 8 | 7 | |

| 2.5 < d < 2.6 | 9 | 8 | 7 | 6 | |

| 2.6 < d < 2.7 | 8 | 7 | 6 | 5 | |

| 2.7 < d < 3 | 7 | 6 | 5 | 4 | |

| 3 < d < 3.1 | 10 | 11 | 10 | 9 | 8 |

| 3.1 < d < 3.2 | 10 | 9 | 8 | 7 | |

| 3.2 < d < 3.3 | 9 | 8 | 7 | 6 | |

| 3.3 < d < 3.4 | 9 | 8 | 7 | 6 | |

| 3.4 < d < 3.5 | 8 | 7 | 6 | 5 | |

| 3.5 < d < 3.6 | 7 | 6 | 5 | 4 | |

| 3.6 < d < 3.7 | 7 | 6 | 5 | 4 | |

If the tensile grade of a wire lies between two tensile grades given in table 3, then the number of reverse bends for the next upper tensile grade shall be chosen.

CAST & HELIX (PITCH)

| Dia(Mm) | Dia Of Block (Mm) | Cast | Helix (Pitch) (Mm) | |

|---|---|---|---|---|

| Cast PITCH OR HELIX | 0.80-1.00 | 300 | 300-450 | 90 under |

| 1.00-1.60 | 400 | 400-600 | 100 under | |

| 1.60-5.50 | 600 | 600-900 | 100 under | |

| 5.00-8.00 | 750 | 750-1125 | 100 under |

Packing

Coil Wt and coil dia for hard wires

| Full Hard Kas | ||||

|---|---|---|---|---|

| from | to | ID” | OD” | Coil Wt Max |

| 0.5 | 0.80 | 8 | 16 | 30 |

| .81 | 1.20 | 14 | 22 | 50 |

| 1.21 | 1.50 | 14 | 22 | 75 |

| 1.51 | 1.70 | 14 | 22 | 100 |

| 1.8 | 5.25 | 18 | 30 | 225 |

Subscribe Newsletter

Subscribe Newsletter