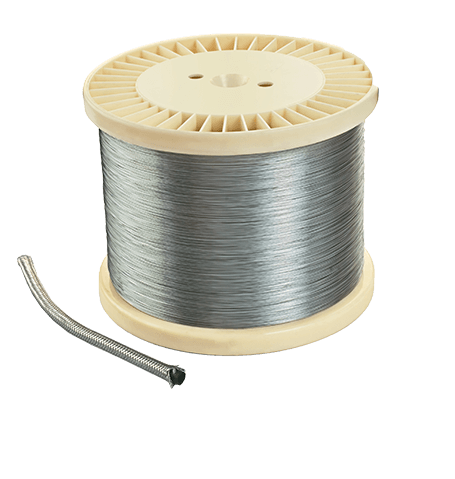

Specification for Soft Annealed Wires in Coils

| Wire Dia Range (mm) | Coil diameter in inches | CoilWt. (Kgs.) | Surface Finish | TotalHt Formers + Pallets Inches | Total Wt. on Formers Kg. | ||

|---|---|---|---|---|---|---|---|

| ID | OD | Min | Max | ||||

| 5.00-8.00 | 24-27 | 33.37 | 100 | 500 | MATIE | 60 | 1500 |

| 5.50-2.50 | 18·22 | 25·30 | 100 | 500 | MATIE | 60 | 1000 |

| 2.49-1.60 | 18·22 | 25·30 | 100 | 500 | MATIE | 60 | 1000 |

| 1.59·1.00 | 12·14 | 20·24 | 50 | 100 | MATIE | 60 | 500 |

Product Range

Stainless Steel Wires are used in Engineering, Chemical, Construction and many other industries besides various type of application in manufacturing of KITCHEN WARES, ORNAMENTS, UTENSilS. Stainless Steel Wires at KEI are manufactured as per INTERNATIONAL STANDARDS as well as in accordance with customer’s specifications.

Special Characteristics

- Produced from Wire rods meeting International standards

- Supplied in annealed, 1/8 hard, 1/4 hard & 1/2 hard, 3/4 hard, full hard conditions. – Drawn to very close tolerance limit.

- Excellent Surface finish.

- Quality Checked at each process stage.

Chemical Composition

- Available in complete range of Stainless Steel as per AIS!. DIN,JIS and BS standards.

Mechanical Properties

| Dia (mm) | AISI 304, 316 | AISI 304l.316l | ||

|---|---|---|---|---|

| Tensile Strength N/mm’ (Kgl/mm’) | Elongation (%) | Tensile Strength N/mm’ (Kgf/mm’) | Elongation (%) | |

| 0.10 – 0.16 | Manufactured in only low carbon grades | 30 min | 785 max (80 max) | 30 min |

| 0.17 – 0.22 | 30 min | 765 max (78 max) | 30 min | |

| 0.23 – 0.40 | 30 min | 745 max (76 max) | 30 min | |

| 0.41 – 0.70 | 833 max (85 max) | 40 min | 745 max (76 max) | 40 min |

| 0.71 – 1.60 | 800 max (82 max) | 40 min | 715 max (73 max) | 40 min |

| 1.61 – 8.00 | 785 max (80 max) | 40 min | 685 max (70 max) | 40 min |

Diameter Tolerances

| Dia (mm) | Tolerance (mm) | Ovality (mm) |

|---|---|---|

| 0.10.0.11 | +/-0.003 | 0.003 |

| 0.12·0.16 | +/-0.005 | 0.005 |

| 0.17 -0.28 | +/-0.007 | 0.007 |

| 0.29 ·0.50 | +/-0.008 | 0.008 |

| 0.51 .0.90 | +/-0.013 | 0.013 |

| 0.91·1.60 | +/-0.020 | 0.020 |

| 1.61-2.80 | +/-0.030 | 0.030 |

| 2.81-6.00 | +/-0.030 | 0.030 |

| 6.00 -8.00 | +/-0.040 | 0.040 |

| Packing specifications | ||

On plastic spools as per OIN standards.

Wire (EPQ) for Kitchenware and Baskets

KEl’s has the ability to manufacture Stainless Steel Wires in bright as well as in matte finish, suitable for kitchenware and basket, grade AISI 304, in various sizes. KEI is a major market player for wires in Electropolish quality, Balls, Pins, Nails and other general application.

Wire (EPQ) for Kitchenware and Baskets

KEI’s Stainless Steel Wire for Scrubber application has very bright smooth finish and its extra softness enables further cold working by the customers.

Specification for Scrubber Application in Spool Packing

| Diameter(mm) | Type of Soool | Unit Weight (Kg) |

|---|---|---|

| 0.80 | DIN355,DIN250 | 40- 45.18- 22 |

| 0.12 to 0.15 | DIN 160,DIN 125 | 3-6,l.5 – 3 |

| 0.15 | OIN200 | 8- 12 |

Mechanical Properties

| Diameter (mm) | Grade | Tensile Strength N/mm'(Kgl/mm) | Finish Method |

|---|---|---|---|

| 0.8 | AISl:304 | 640-830 (65-85) | Annealed |

| AISl:430 AISl:434 |

490-640(50-65) | ||

| 0.12 yo 0.15 | AISl:304 | Max 758 (Max 80) | Annealed |

| 0.12 yo 0.15 | AISl:430 AISl:434 |

Min 1170 (Min 120) | Wet drawn |

Mechanical Properties Along With Packing Details

Specification for 1/8, 1/4, 3/4 Hard Temper Wires

| Temper | Wire Dia Range | Coil Dia Range (Inches) | Coil Weight | Surface Finish | Total Wt. on former | |

|---|---|---|---|---|---|---|

| 1/8 hard, 120 KSI Max. | MM | ID | OD | Kg | Kg | |

| 5.00-8.00 | 24-27 | 33-37 | 250-400 | Bright/Matte | 1500 | |

| 4.50-6.00 | 18-22 | 25-30 | 100-150 | Stearate Coated | 1000 | |

| 4.50-6.00 | 18-22 | 25-30 | 100-150 | Matte (Clean) | 1000 | |

| 4.50-6.00 | 18-22 | 25-30 | 100-150 | Bright | 1000 | |

| 2.00-4.50 | 18-22 | 25-30 | 100-1000 | Stearate Coated | 1000 | |

| 2.00-4.50 | 18-22 | 25-30 | 100-1000 | Matte (Clean) | 1000 | |

| 2.00-4.50 | 18-22 | 25-30 | 100-1000 | Bright | 1000 | |

| 1.25-2.00 | 18-22 | 25-30 | 50-150 | Stearate Coated | 1000 | |

| 1.25-2.00 | 18-22 | 25-30 | 50-150 | Matte (Clean) | 1000 | |

| 1.25-2.00 | 18-22 | 25-30 | 50-150 | Bright | 1000 | |

| 0.90-1.25 | 10-12 | 19-21 | 25-90 | Stearate Coated | 500 | |

| 0.90-1.25 | 10-12 | 19-21 | 25-90 | Matte (Clean) | 500 | |

| 1/4 hard, 128 KSI Max. | 0.90-1.25 | 10-12 | 19-21 | 25-90 | Bright | 500 |

| 4.50-6.00 | 18-22 | 25-30 | 100-150 | Stearate Coated | 1000 | |

| 4.50-6.00 | 18-22 | 25-30 | 100-150 | Matte (Clean) | 1000 | |

| 4.50-6.00 | 18-22 | 25-30 | 100-150 | Bright | 1000 | |

| 2.00-4.50 | 18-22 | 25-30 | 100-1000 | Stearate Coated | 1000 | |

| 2.00-4.50 | 18-22 | 25-30 | 100-1000 | Matte (Clean) | 1000 | |

| 2.00-4.50 | 18-22 | 25-30 | 100-1000 | Bright | 1000 | |

| 1.25-2.00 | 18-22 | 25-30 | 50-150 | Stearate Coated | 1000 | |

| 1.25-2.00 | 18-22 | 25-30 | 50-150 | Matte (Clean) | 1000 | |

| 1.25-2.00 | 18-22 | 25-30 | 50-150 | Bright | 1000 | |

| 0.90-1.25 | 10-12 | 19-21 | 25-90 | Stearate Coated | 500 | |

| 0.90-1.25 | 10-12 | 19-21 | 25-90 | Matte (Clean) | 500 | |

| 0.90-1.25 | 10-12 | 19-21 | 25-90 | Bright | 500 | |

Note : Totel height of former & pallet together is 1524 mm Max.

Packing – Specification for Scrubber Application in Drum Packing

| Size rangs(mm) | Drum | Dimensions | Inches | Weight of wire Kg |

|---|---|---|---|---|

| 0.80 – 1.20 | OD 23″ | Core 10″ | HT 33″ | 200 |

Stainless Steel Wires for Wall Tie/Tying WireslRe-inforcement Bars

KEl’s Stainless Steel Wire find application in construction industry. KEI manufactures Stainless Steel Wires in grades of 302. 304. 316. 316Ti. in bright as well as annealed condition. suitable to manufacture wall tie. tying wire as well as re-inforcement bars for building and construction. The sizes offered are 0.9 mm to 8.0 mm.

Subscribe Newsletter

Subscribe Newsletter